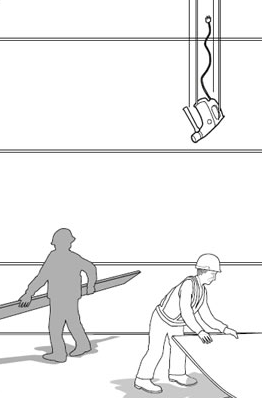

Image from WorkSafeBC Hazard Alert 2015-01 Worker seriously injured by falling drill

The prime contractor at a worksite is responsible for the safety of all workers and people on the site.

This is especially important on construction sites, where there are often workers from several different trades working simultaneously. A case in point is a tragic incident that left one construction worker with permanent, serious injuries after he was struck by a drill that fell 59 metres (195 feet) from the 27th floor.

This incident is described in a new WorkSafeBC Hazard Alert: Worker seriously injured by falling drill. The investigation found a prime contractor had “failed to adequately instruct the construction safety officer (CSO) at this jobsite by providing site-specific safe work procedures for working above or below other workers.”

For more insight into this type of incident, I called CSO Samuel Livingstone, an OHS professional who focuses on education and leadership.

“Normally you don’t have workers working below and above each other. If workers are working on a patio or outside deck, you tape off the area below, so if anything does fall, it won’t affect them,” Sam said. “Or if you have to have workers working above others, you install a scaffold with a platform so that if stuff falls down it doesn’t land on the workers below.”

I asked how a prime contractor is expected to work with a CSO.

“The prime contractor writes policies and procedures typically and the CSO enforces them,” said Sam, describing how the main purpose of the prime contractor is to coordinate trades on their site.

This responsibility is laid out in Part 20.3 of the Occupational Health and Safety Regulation, which requires prime contractors to “appoint a qualified coordinator for the purpose of ensuring the coordination of health and safety activities for the location.”

“Obviously the CSO was not informed properly about his responsibilities on how to do it,” said Sam, who (for the record) was not involved in the investigation and only has details on it from the Hazard Alert.

He said tool lanyards can be helpful in preventing this type of injury. They haven’t caught on much in construction, but are being used increasingly in the oil and gas industry.

“The lanyard is wrapped around your wrist or your tool belt to the tool, so if something falls, it doesn’t go more than your feet basically,” he said.

I asked Sam if he had any advice for a prime contractor on working with a CSO.

“Make sure your CSO is currently certified. That demonstrates they are maintaining their own professional development and knowledge base, as opposed to someone who just took a two-week course and hasn’t done anything since then,” he said. “And the other piece of advice is to make sure that you’re properly planning the work, so that all the trades working below can be coordinated properly.”

Thanks to Sam for talking with me – and, if you have any experiences to share, please do add them in the Comments box below.

I am a fully licensed crane operator, in the past 12 months i have worked for 5 union and non union companies in BC, there was only one company that did a complete on-boarding (indoc competency etc) it is no surprise that we continue to have near misses and incidents when management doesn’t have the knowledge or is willing to obtain it. One site issued PPE (hard hat 2 holes drilled into it, PFD to small) Another manager stated crane operators do not follow CSA Z150. I could write a book with pictures on my last 12 months that would scare any sensible new worker prospects from joining the construction industry.