From WorkSafeBC’s Manufacturing Safety Alert 12-02

I read a tragic and disturbing story about the danger of getting long hair caught in machinery. A 25-year-old Ohio worker was “scalped” on her sixth night at a new job in an auto parts company, according to this story in Ohio.com.

“Her long brown hair, which hung to midback but was always pulled back for work, became tangled in the machine,” reads the story, which reports the incident is under investigation by OSHA.

The machine ripped her scalp from “just above her eyebrows backward toward her neck,” and she called for coworkers to stop the machine. She was released from the machine by paramedics and 75 percent of her scalp was re-attached in emergency.

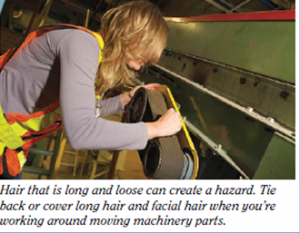

Soon after I heard about the young Ohio worker, I saw a new safety alert for the manufacturing industry from WorkSafeBC – The Hazards of Loose Clothing, Gloves, Long Hair, and Jewellery.

“Whether you’re making food products, furniture, sheet metal, or anything else, if you work in the manufacturing industry you will be exposed to the hazards of machinery or equipment with moving parts. Loose clothing, gloves, jewellery, and long hair can get caught in moving parts and cause serious injury or death,” reads the alert.

“In the five years between January 1, 2006, and December 31, 2010, 350 workers [in BC] were injured when their clothing, gloves, jewellery, or hair was caught by moving equipment or machinery parts. Fifty-six of these workers received fractures and another 67 of them had to have their fingers or limbs amputated.”

Danger of gloves near machinery

A UK factory worker lost his fingertip to the first knuckle when his glove was entangled in a drill bit. The news release quotes HSE inspector Hugh Emment, who said: “As this incident illustrates, the wearing of gloves is often a significant factor as it greatly increases the risk of entanglement and serious injuries.”

The HSE story also reports the 21-year-old worker “…had not received any information, instructions or training on using the drill and that it had been unguarded at the time of the incident. Also the operation of the drill had not been risk assessed and there was no formal system in place for checking the drill guard.”

Young workers

Both the workers I’ve mentioned – whose recovery I wish the very best for – were young workers (15 to 24). This age group is injured more often than any other and many online resources for them exist, including the following: